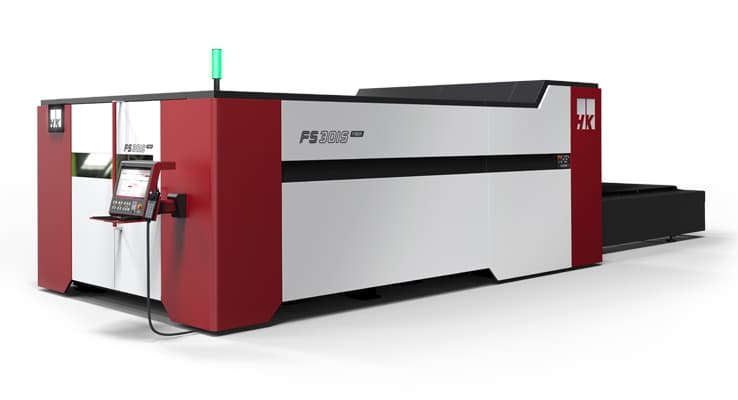

Precision Fabrication Machinery Division

Precision fab is possible in thousands of shops. In order to stand out among the crowd, it is essential to provide quality parts and on time. Service is what we are all about. We work hard to provide the best customer service. A weekly report is sent to you that details what is happening on your side. We are honest about any delays on your side. We won't always get it right. But we'll get it right. You don't need to believe what we say. See our feedback from customers.

The manufacture of medical systems and instruments requires dependable automation solutions from a dependable partner.